Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News at Linke

News from National Cable And Wire Manufacturing Company.

Design and Manufacturing Process of EEG Cable OEM

EEG (electroencephalogram) cables play a crucial role in the fields of neuroscience and medical research. These cables are responsible for connecting electrodes to the scalp, enabling the measurement and recording of electrical activity in the brain. In this blog post, we will delve into the intricate design and manufacturing process of EEG cable OEM (Original Equipment Manufacturer).

Design Phase

The design phase serves as the foundation for the manufacturing process of OEM EEG cables. It involves a comprehensive understanding of the customer’s requirements and specifications. Our dedicated design team works closely with the customer to determine the number of electrodes, cable length, connector type, and other essential features. We also take into consideration factors such as signal quality, comfort, and durability.

Once the requirements are finalised, our design team creates a detailed design plan. This plan encompasses the layout of the electrodes, the routing of the cables, and the selection of materials. We also prioritise factors such as noise reduction and shielding to ensure accurate and reliable signal transmission.

Material Selection

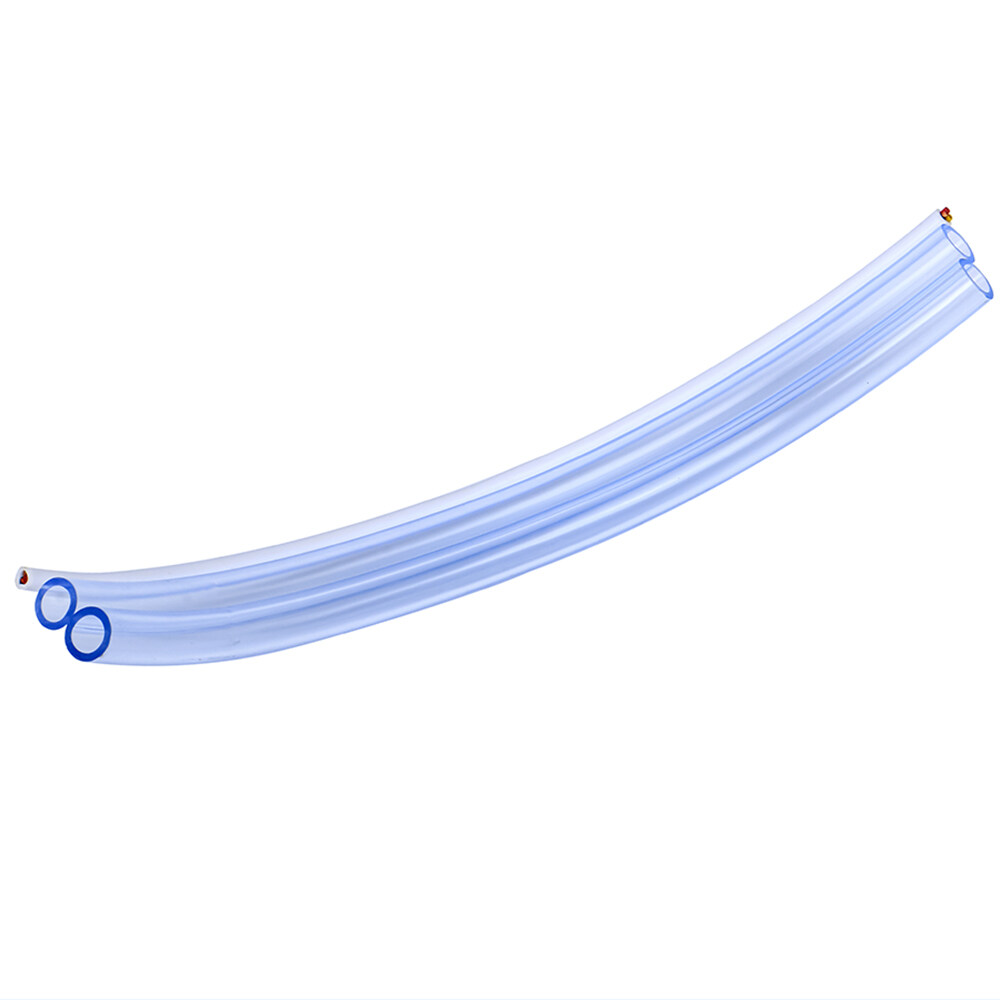

The selection of materials is a critical aspect of the manufacturing process of OEM EEG cables. We meticulously choose materials that are flexible, lightweight, and comfortable for the patient. Our design team selects high-quality materials that are biocompatible and safe for use on the scalp. We also consider factors such as electrical conductivity and insulation properties to ensure optimal performance.

The connectors used in our EEG cables are crafted from medical-grade materials such as stainless steel or gold-plated brass. These materials guarantee a reliable and secure connection between the electrodes and the recording device.

Cable Assembly

Once the design and material selection are finalised, we proceed to the cable assembly phase. This phase involves the precise assembly of the cables, connectors, and electrodes. Our skilled technicians cut the cables to the desired length and strip them to expose the conductive wires.

The electrodes are then meticulously attached to the cables using specialised techniques such as soldering or crimping. The connectors are also securely attached to the cables, ensuring a reliable connection. Our assembly process adheres to strict quality control procedures to ensure the accuracy and reliability of our EEG cables.

Testing and Quality Control

After the cable assembly is complete, our EEG cables undergo rigorous testing and quality control procedures. These tests include assessing electrical conductivity, signal integrity, and noise reduction. We also test the cables for durability and flexibility to ensure they can withstand repeated use.

Our quality control team meticulously inspects each cable for any defects or inconsistencies. They verify that the cables meet the customer’s specifications and requirements. Any faulty cables are rejected, and we make the necessary adjustments to prevent similar issues in the future.

Packaging and Delivery

The final step in the manufacturing process of OEM EEG cables is packaging and delivery. We take great care in packaging the cables to ensure they are protected during transportation. The packaging may include individual cable pouches or boxes, depending on the customer’s requirements.

Our cables are then shipped to the customer, ready for use in EEG recordings and research. As Dongguan Linke Cable Technology Co., Ltd., we pride ourselves on providing high-quality EEG cables that meet our customers’ requirements and deliver accurate and reliable brain activity measurements.

In conclusion, the design and manufacturing process of EEG cable OEM involves meticulous planning, material selection, cable assembly, testing, and quality control. This process ensures the production of top-notch EEG cables that meet our customers’ needs and provide accurate and reliable brain activity measurements.

About Dongguan Linke Cable Technology Co., Ltd.

Dongguan Linke Cable Technology Co., Ltd. is a leading manufacturer and supplier of high-quality cables and connectors. We specialise in the design and production of EEG cables, providing OEM services to meet our customers’ specific requirements. With our state-of-the-art manufacturing facilities and a dedicated team of professionals, we are committed to delivering superior products and exceptional customer service. Contact us today to learn more about our EEG cable OEM solutions.