Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News at Linke

News from National Cable And Wire Manufacturing Company.

How to Choose the Right Connectors for Robot Cable Bulk

When it comes to industrial automation, selecting the right connectors for robot cable bulk is essential for ensuring optimal performance and reliability. With the increasing complexity and sophistication of robotic systems, choosing the right connectors can make a significant difference in the overall functionality and efficiency of the robot. In this blog post, we will discuss some key factors to consider when selecting connectors for robot cable bulk.

Electrical Requirements

The first consideration when selecting connectors for robot cable bulk is the electrical requirements of the system. It is important to determine the voltage, current, and signal requirements of the robot and choose connectors that can handle these specifications. Additionally, considering the number of pins or contacts required for a specific application is essential.

Environmental Conditions

Robots are often used in harsh and demanding environments, such as manufacturing plants or outdoor settings. Therefore, it is crucial to select connectors that can withstand these conditions. Factors such as temperature, humidity, dust, and vibration should be taken into account when choosing connectors. Look for connectors that have high IP ratings, indicating their resistance to water and dust ingress.

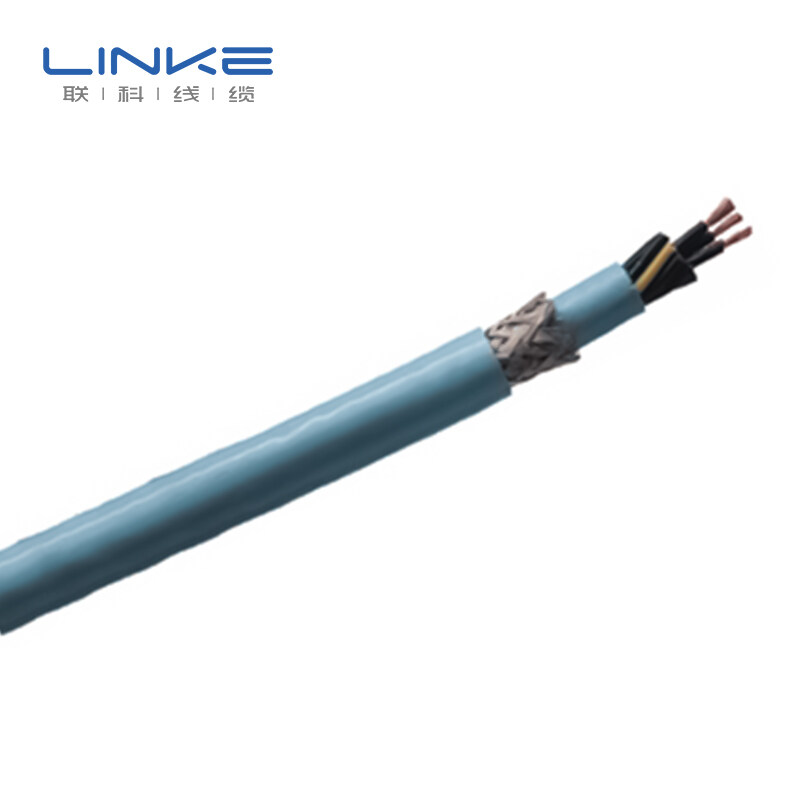

Mechanical Durability

The connectors used in robot cable bulk should be mechanically durable to withstand the constant movement and stress that robots undergo. They should be able to withstand repeated mating and unmating cycles without compromising their performance. Connectors with robust locking mechanisms and strain relief features are ideal for ensuring a secure and reliable connection.

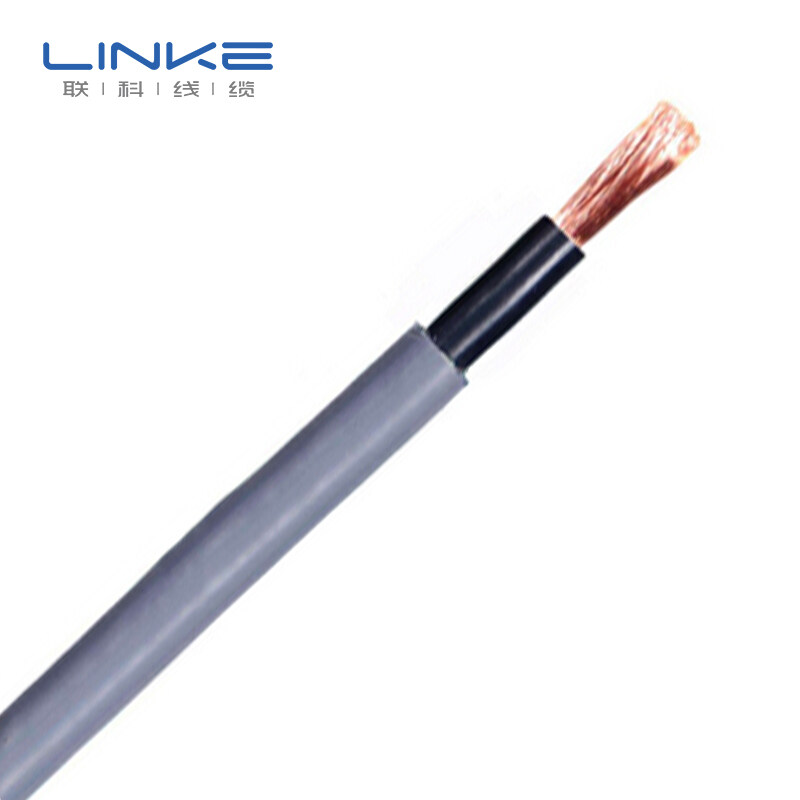

Size and Form Factor

The size and form factor of the connectors should be considered to ensure compatibility with the robot’s design and available space. Compact and low-profile connectors are often preferred in robotic applications where space is limited. Additionally, connectors with easy-to-use features, such as colour-coded or keyed mating interfaces, can simplify the installation and maintenance processes.

EMI/RFI Shielding

Electromagnetic interference (EMI) and radio frequency interference (RFI) can negatively impact the performance of robotic systems. Therefore, it is important to select connectors that provide adequate EMI and RFI shielding to minimise the risk of signal interference. Connectors with metal shells or shielding options can help protect against EMI and RFI.

Connector Mating and Unmating

The ease of mating and unmating connectors is another important consideration. Connectors that are difficult to mate or unmate can lead to increased downtime and maintenance costs. Look for connectors that offer a smooth and secure mating process with features such as audible clicks or tactile feedback to ensure a proper connection.

Industry Standards and Compatibility

It is advisable to choose connectors that comply with industry standards and are compatible with existing systems or equipment. This ensures interoperability and simplifies the integration process. Additionally, selecting connectors from reputable manufacturers with a proven track record in the robotics industry can provide assurance of quality and reliability.

In conclusion, selecting the right connectors for robot cable bulk is a critical decision that can significantly impact the performance and reliability of robotic systems. By considering factors such as electrical requirements, environmental conditions, mechanical durability, size and form factor, EMI/RFI shielding, connector mating and unmating, and industry standards, you can make an informed choice that meets the specific needs of your robotic application.