Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News at Linke

News from National Cable And Wire Manufacturing Company.

Unlocking the Potential of Custom Composite Power Cables

Introduction

In an age where efficient energy transmission is paramount, custom composite power cables have emerged as a cornerstone technology, revolutionizing the way we distribute power across various industries. These innovative cables, meticulously engineered with advanced materials and structures, play a pivotal role in ensuring a reliable and sustainable energy supply. In this article, we delve into the intricate world of custom composite power cables, exploring their composition, advantages, and diverse applications across industries such as energy, telecommunications, and transportation.

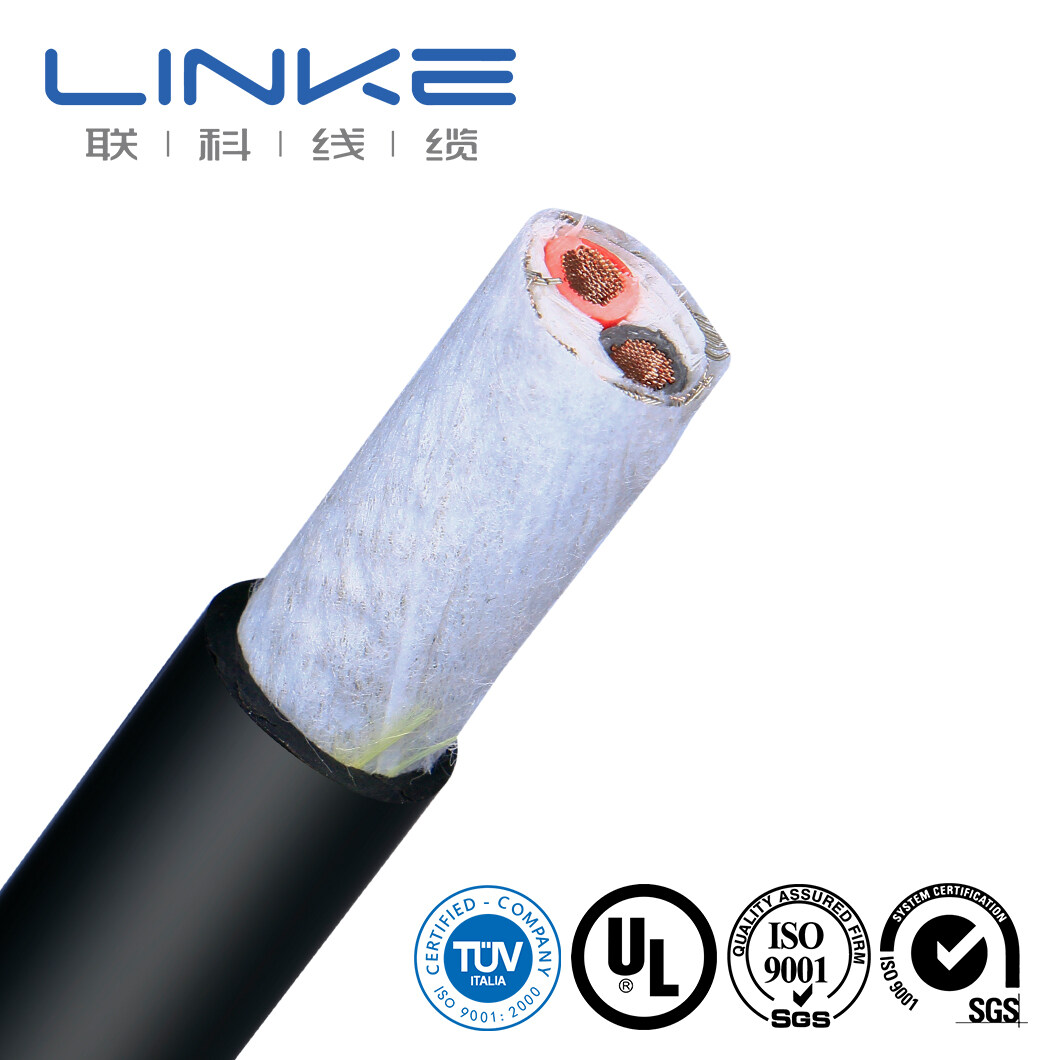

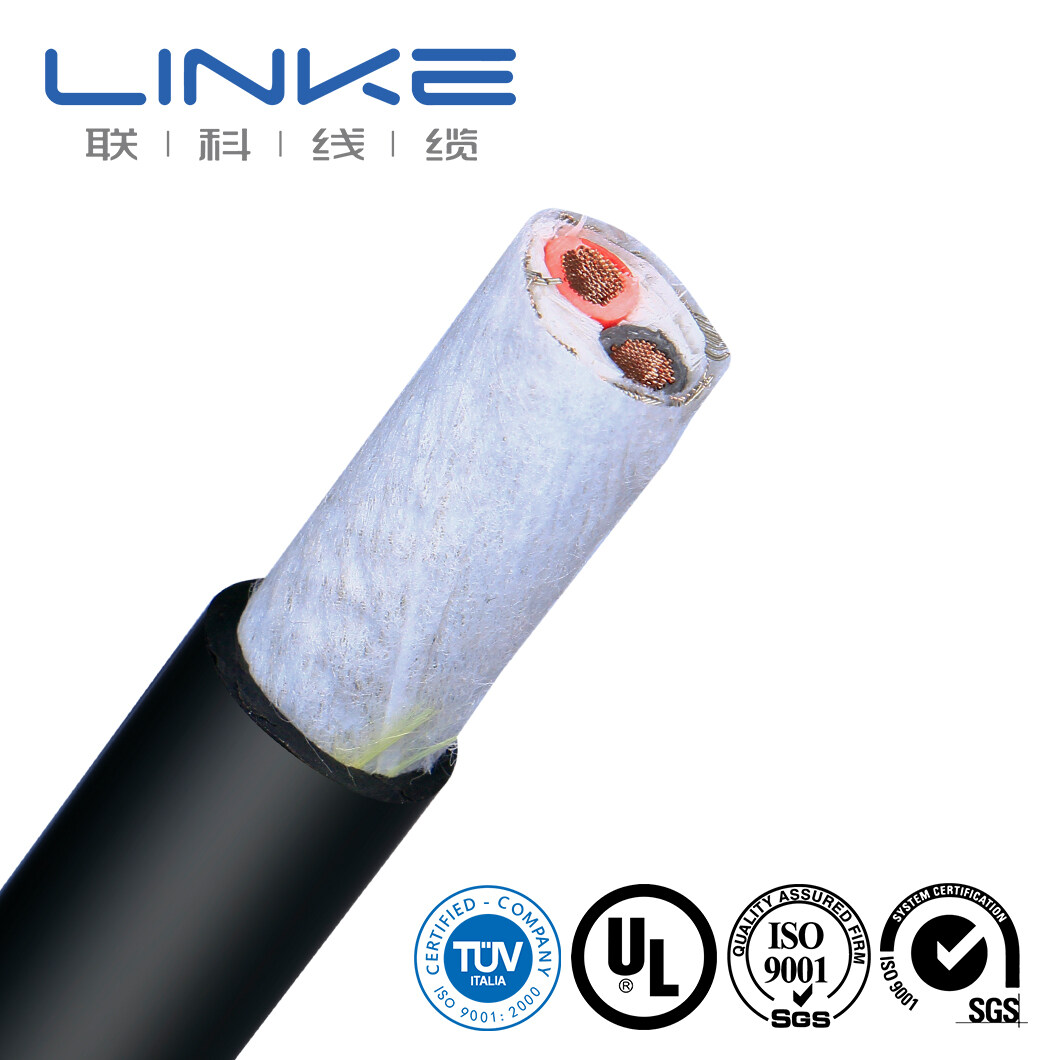

Composition and Structure

Custom composite power cables represent a paradigm shift from traditional cables, incorporating a sophisticated blend of materials to achieve superior performance. Unlike their conventional counterparts, which typically rely on metals like copper or aluminum, custom composite power cables integrate composite materials such as carbon fiber, fiberglass, and polymers. This unique composition endows them with unparalleled durability, flexibility, and resistance to environmental factors.

At the heart of custom composite power cables lies a carefully engineered structure designed to optimize performance and reliability. Multiple layers of insulation and shielding are strategically applied to safeguard the conductive core from external threats, ensuring seamless power transmission even in the harshest conditions. Moreover, advancements in manufacturing techniques have enabled the production of custom composite cables with varying voltage ratings, conductor sizes, and insulation materials, catering to a diverse array of applications.

Advantages of Composite Materials

The adoption of composite materials in custom power cables confers numerous advantages over traditional alternatives. One of the most notable benefits is enhanced durability. Unlike metal-based cables, which are susceptible to corrosion and fatigue, composite cables exhibit exceptional resistance to wear and degradation, prolonging their service life and reducing maintenance costs.

Flexibility is another key advantage offered by composite power cables. Their lightweight and pliable nature enables easy installation and maneuverability, especially in confined spaces or challenging terrain. This flexibility translates into significant savings in terms of time and labor, making composite cables an attractive choice for both large-scale infrastructure projects and industrial applications.

Furthermore, composite materials possess inherent insulating properties, providing superior protection against electrical faults and minimizing the risk of downtime or system failures. Additionally, their resistance to moisture, temperature extremes, and chemical exposure makes them ideal for demanding environments such as offshore installations or industrial facilities.

Applications

The versatility of custom composite power cables extends across a broad spectrum of applications, ranging from underground power distribution to specialized industries such as aerospace and industrial automation.

Underground Power Distribution: In urban environments where space is at a premium, underground power distribution systems are increasingly relied upon to deliver electricity to homes, businesses, and public infrastructure. Custom composite power cables play a vital role in these systems, offering compact dimensions and robust insulation to withstand the rigors of underground installation while ensuring efficient power delivery.

Offshore Wind Farms: Offshore wind farms represent a burgeoning sector in the renewable energy landscape, harnessing the power of wind to generate clean electricity. Custom composite power cables are well-suited for these marine environments, withstanding saltwater corrosion and the mechanical stresses associated with deep-sea installation. Their lightweight construction also reduces the load on support structures, facilitating cost-effective deployment and maintenance.

Aerospace Applications: In the aerospace industry, where weight savings and reliability are paramount, custom composite power cables find extensive use in aircraft wiring systems. Their low weight and high strength-to-weight ratio contribute to fuel efficiency and aircraft performance, while their resistance to electromagnetic interference ensures uninterrupted communication and navigation signals.

Industrial Automation Systems: Industrial automation relies heavily on robust and dependable power transmission solutions to support the operation of machinery and equipment. Custom composite power cables offer the flexibility and resilience required for dynamic industrial environments, where they are exposed to mechanical vibrations, thermal fluctuations, and chemical exposure. Their ability to withstand these harsh conditions ensures continuous operation and minimizes downtime, enhancing productivity and efficiency.

Conclusion

Custom composite power cables represent a testament to human ingenuity and innovation, pushing the boundaries of traditional cable technology to meet the evolving needs of modern society. With their advanced materials, superior performance, and diverse applications, these cables are poised to play a central role in shaping the future of energy transmission and infrastructure development. As we continue to explore new frontiers in technology and engineering, custom composite power cables will undoubtedly remain at the forefront, driving progress and sustainability across industries.