Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Speciality Wire And Cable

Underwater Cable

The underwater cables with a simple yet dependable structure are designed to overcome their weight and float on the water’s surface, while also providing excellent waterproof performance. Even after long-term use, our cables maintain their alignment, preventing misalignment, twisting, or deformation between the cable cores. This makes them ideal for long-term underwater work, ensuring that you can rely on them for years to come.

Servo Tracking Cable

The servo tracking cable is a servo system-specific cable. The cable possesses a number of distinct properties, including high flexibility, wear resistance, folding resistance, oil resistance, bending resistance, tensile resistance, twist resistance, anti-interference, anti-aging, and so on, allowing it to be used as a connection and control cable. The servo-specific cable of the servo system is perfectly combined with the operation and use of the servo motor, greatly improving the servo motor's working efficiency (control motor, execution motor).

Custom Special Wire

Custom wires are wires that are tailored to your specific requirements. If you find that existing products don’t quite meet your needs, or if a modified product would work better for your application, ordering custom wires is a great solution. More detailed information needs to know, welcome to just contact with us!

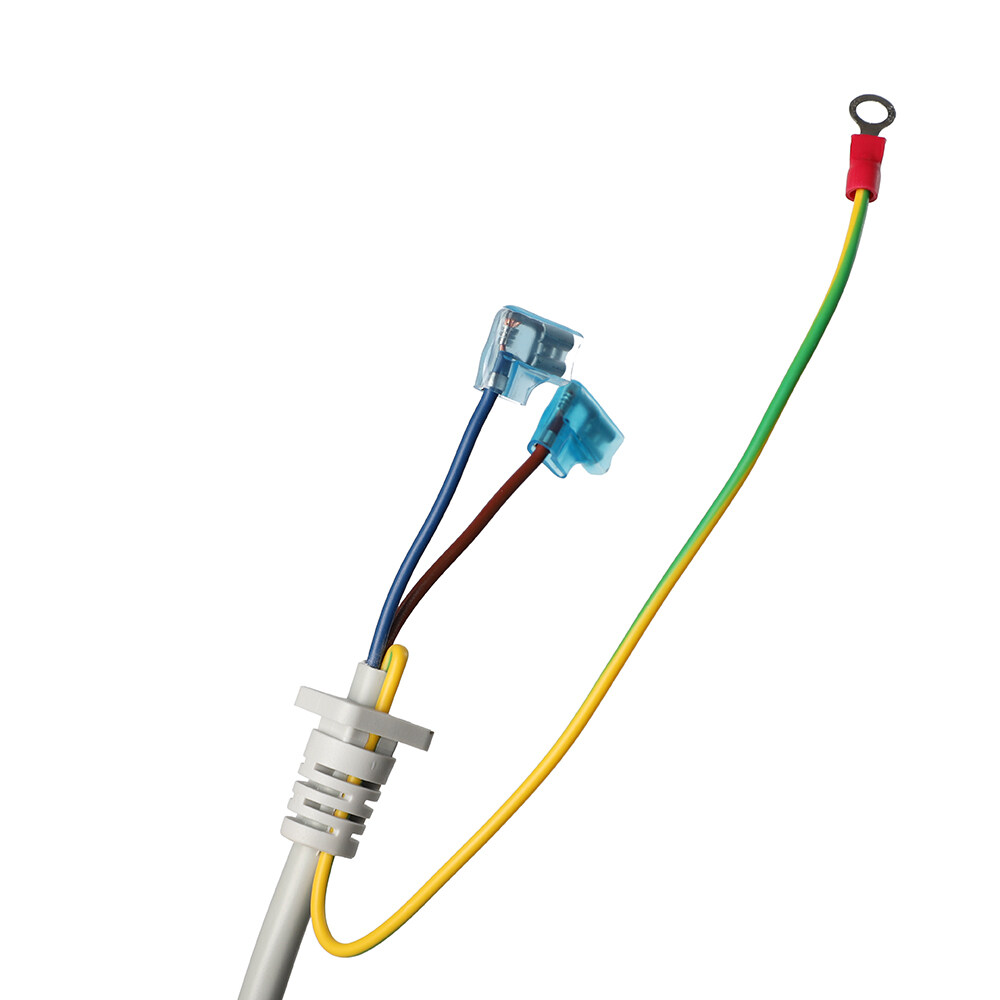

Electrical Wiring Harness

Electrical wiring harnesses are crucial components in a wide range of electrical systems, from automobiles to industrial machinery. They are made up of various components, including wires, electrical tape, straps, and conduits, all of which work together to ensure the safe and efficient transmission of electrical signals. These harnesses are carefully designed and manufactured to meet the specific needs of each application, ensuring that they are reliable and effective.

Wiring Harness Assembly

Wiring harness assembly is the process of bundling wires and cables together in a systematic manner to create a single, organized unit. This unit is then used to connect various electrical components in a piece of equipment or machinery. Wiring harnesses are designed to be highly resilient to damage, reduce the risk of electrical faults and fires, and save manufacturing time.

Custom Spring Cable

Spring cables, also known as spiral cables, are essential in almost every industry. They are designed to connect devices and utilize elasticity to provide flexibility and durability. These cables are highly elastic, with an elongation length that can reach up to 3.5-4 times the original spring length. They are also resistant to cold, flames, oil, and abrasion, making them suitable for a wide range of applications.

Automotive Wiring Harness

The automotive wiring harness is like the nervous system of a car - it’s the backbone of the entire electrical network. It’s made up of copper contact terminals (connectors) and wires that are crimped together to create a connected circuit assembly. Without the wiring harness, a car’s electrical system wouldn’t function.