Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

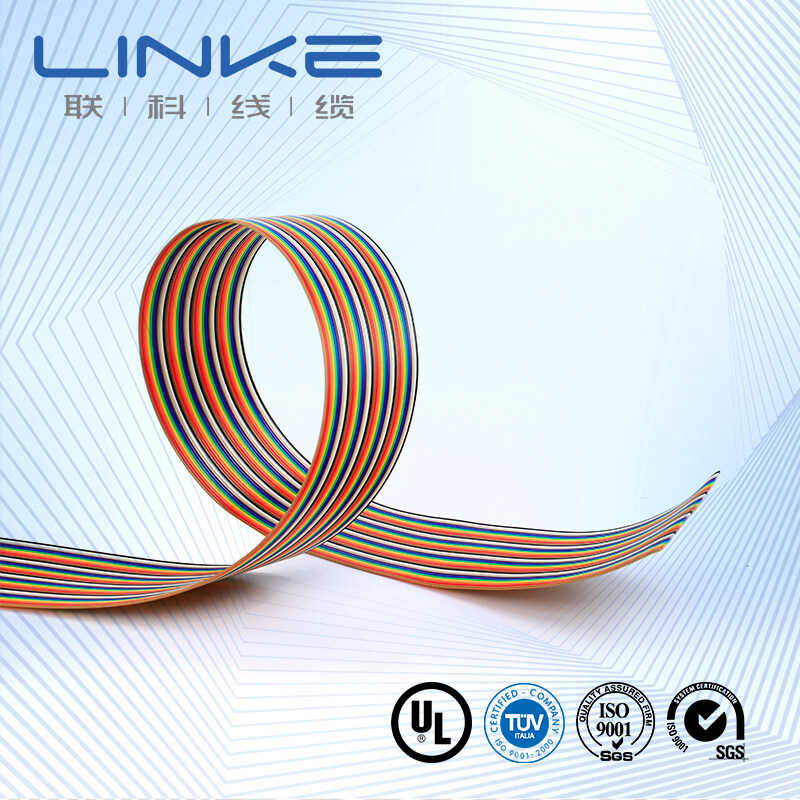

3*2.5+2*0.5 16A EV Car Charging Cable

An EV charging cable is a cable used to connect an electric vehicle to a charging station or other power source. These cables are designed to safely and efficiently transfer power from the charging station to the vehicle’s battery, allowing the battery to be charged and the vehicle to be powered. EV charging cables come in a variety of lengths and configurations, and are typically made with high-quality materials that are designed to withstand the rigors of daily use.

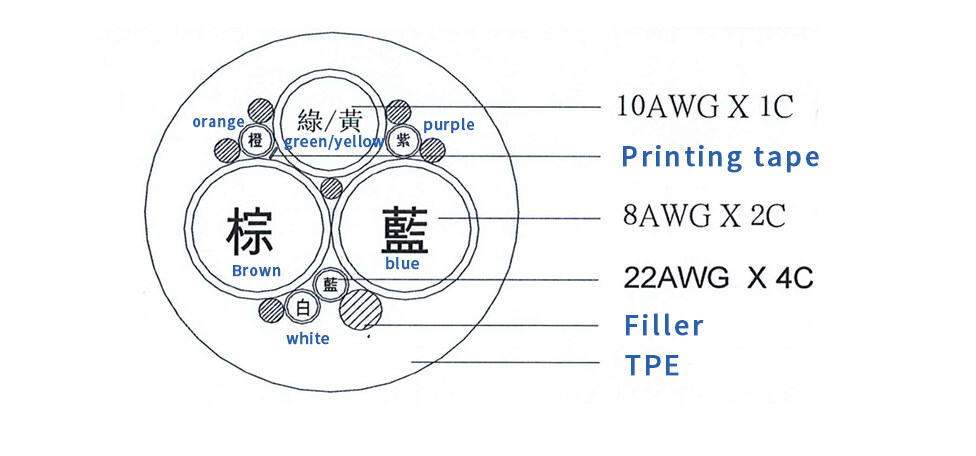

EV Charging Cable Specification

Rated Voltage: AC 1000V/DC1500V

Time for Short Circuit: 200°C for 5s

Excellent Low Temperature Toughness: passed 2PfG1908-35℃ low temperature bending test, -35℃ cold elongation test, -25℃ cold impact test.

Conductor: tinned or non-tinned annealed soft twisted copper (IEC60228 type 6 conductor)

Insulator: XLPO (125-degree irradiation cross-linked polyolefin)

Sheath: XLPO (125-degree radiation cross-linked polyolefin)

Shielding: Tinned copper wire braided shielding, density greater than or equal to 85%, wrapped with aluminum foil after shielding. (optional)

EV Charging Cable Feature

[Wide Temperature Range]: Electric vehicle cables are designed to operate in a wide range of temperatures, with a working environment temperature range of -40°C to +125°C. The maximum line temperature of these cables is 125°C, ensuring reliable performance even in high-temperature environments.

[Serious Check and Production Standard]: Electric vehicle cables are made with insulation and sheath materials that are designed to provide excellent flexibility and meet the EU ROSH requirements. Specifically, these cables use XLPO (125-degree irradiation cross-linked polyolefin) for both the insulation and sheath, which is a high-quality material that is known for its durability and flexibility. By using XLPO, electric vehicle cables are able to provide safe and reliable performance while also meeting important environmental and safety standards.

[Multiple Strong Performance]: Electric vehicle cables are designed to be highly resistant to a variety of environmental factors, including cold temperatures, wear and tear, oil, acid and alkali, water, and UV radiation. These cables are also designed to withstand external pressure and thermal stress, ensuring reliable performance in a variety of conditions.

[High Flame Retardancy]: Electric vehicle cables have passed the single vertical burning test (2PFG 1908), which is an important safety standard for cables used in electric vehicles. This test ensures that the cables are able to withstand high temperatures and resist burning in the event of a fire, helping to prevent the spread of flames and protect the vehicle and its occupants.

EV Charging Cable Advantages

[High Flexibility]: The minimum bending radius of the EV charging cable can reach 6*OD (nominal diameter of the cable), easy to install and use.

[Excellent Resistance to External Pressure and Thermal Stress]: The electric vehicle cables have passed a series of rigorous tests, including the 2PfG1908 vehicle pressure test, high temperature pressure test, and anti-cracking test.

For more information about EV charging cable, please kindly contact us at any time, we are glad to answer for you. If you want to find a partner, hope that we will be your best choice.