Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

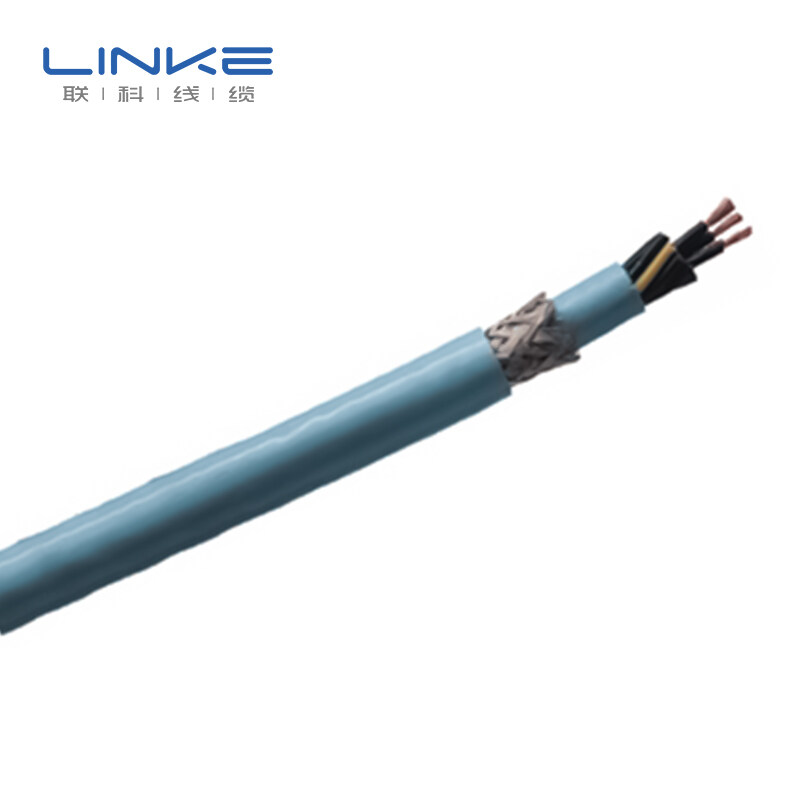

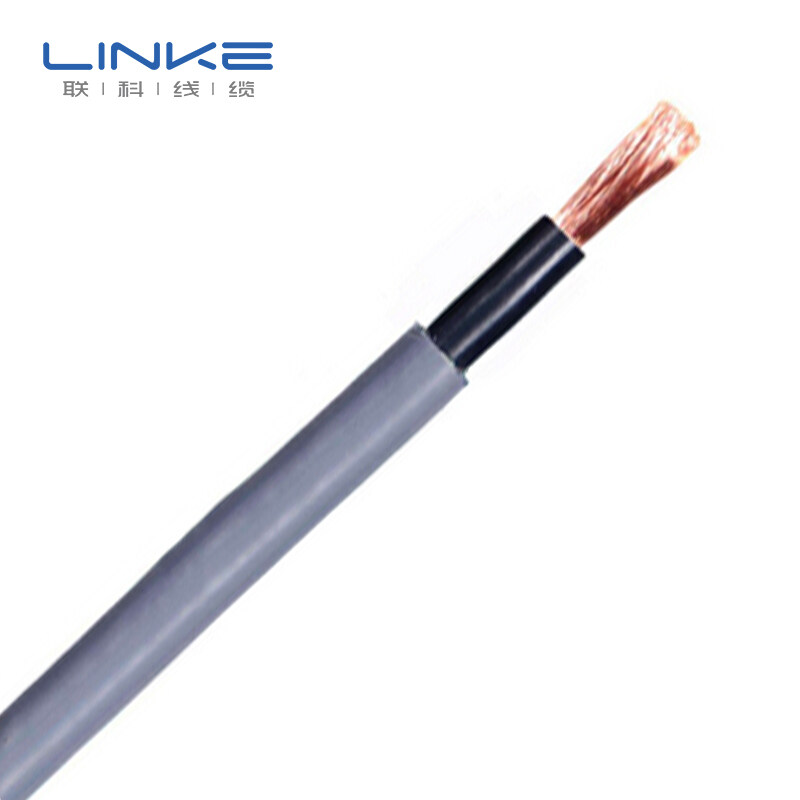

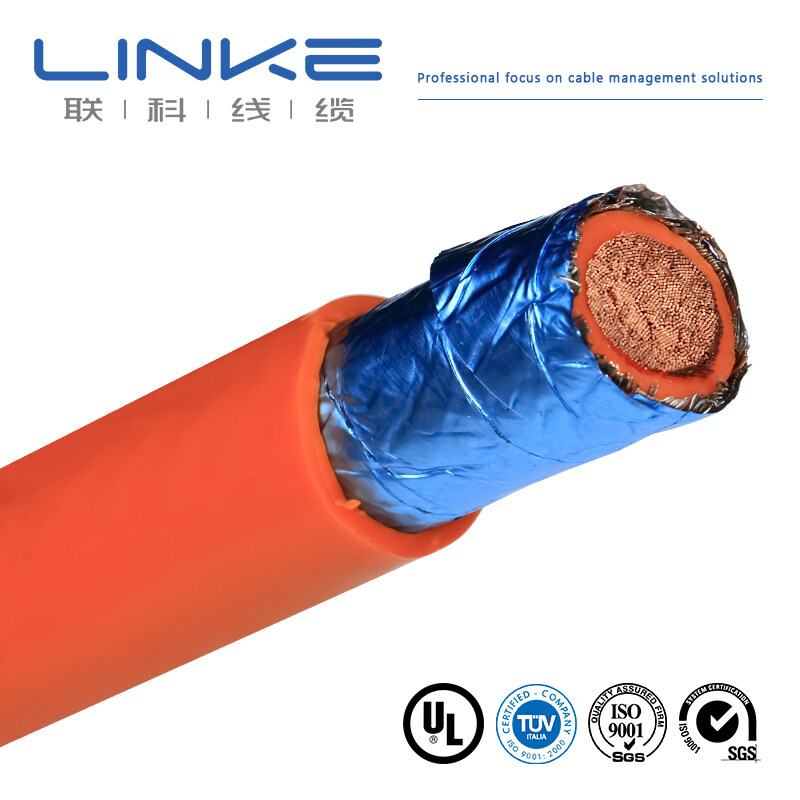

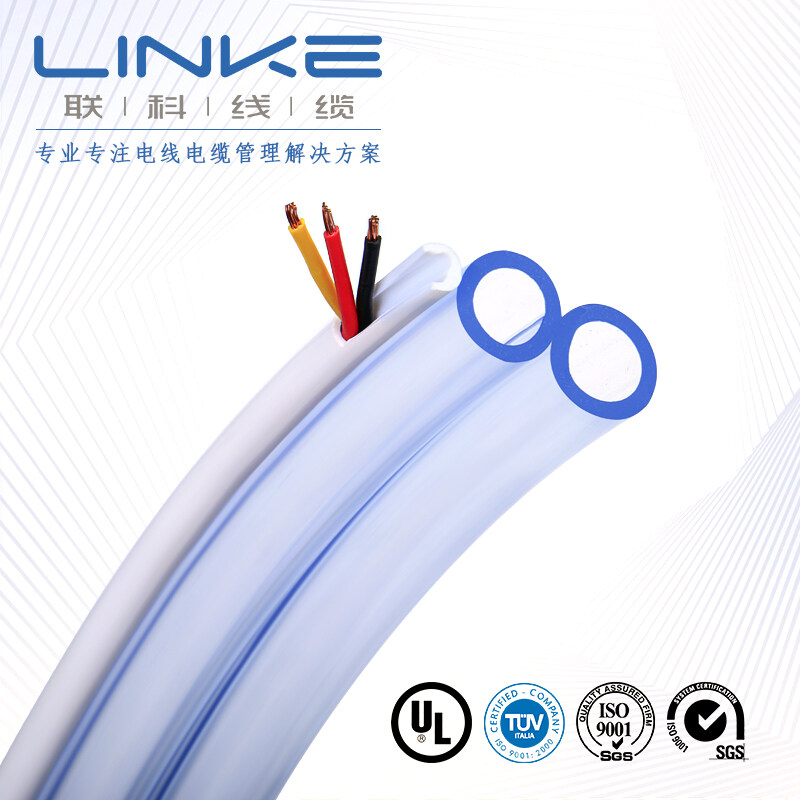

OEM-ODM Robot Cable

Robot cables need to be durable and flexible to handle repeated bending and twisting. They also need to withstand extreme temperatures, oil, and chemicals. These cables are designed to handle mechanical pressure and are essential for the proper functioning of robots. We are professional OEM robot cable manufacturer, providing cheap price and various cables that you need!

OEM-ODM Robot Cable Description

Robot cables are built tough to handle mechanical pressure. They need to be both durable and flexible to withstand repeated bending and twisting. In addition, many robotic cable applications require them to withstand extreme temperatures, oil, and chemicals. These cables are crucial for the proper functioning of robots.

OEM-ODM Robot Cable Feature

[±90° Bending]: 3 million times (R: 8*OD, S: 30 times/min, L: 0.2~0.5kg)

[Twisting Test]: 3 million times (L: 500mm, S: 30 times/min, A: ±180°)

[High Quality Copper Wire]: The robot cable with a multi-core ultra-fine aluminum alloy is designed to be both strong and lightweight.

[Good Resistance]: The robot cable is built to last with an extremely high compressive strength, wear resistance, and heat-resistant insulation made from materials like ETFE.

[Suitable Pitch Diameter Design]: The robot cable ensures maximum flexibility, ductility, bending strength, and resistance to bending and twisting. Moreover, the stranded wire construction allows for greater durability and reliability.

[Excellent Performance]: It has outstanding resistance to acids and alkalis, as well as weather and organic solvents. It can withstand high temperatures and low temperatures, making it a versatile choice for a variety of applications.

OEM/ODM Standard Robot Cable Advantages

[Good Wear Resistance]: Good wear resistance is a requirement that robot cables must meet because the long-term movement of the cable will cause damage to the inside of the core wire. If the wear resistance of the cable is not good, it will affect the internal core wire transmission, so that the control actuator cannot be used normally, and it will also cause safety hazards. Therefore, the robot cable selected for use must have stable and good wear resistance.

[Strong Signal Transmission Ability]: The robot mainly works according to the instructions issued by the computer, but how the computer signal can be transmitted to the machine driver mainly depends on the cable. If the quality of the cable is good, the transmitted signal time is short and very accurate, but if the quality of the cable used is not good, it will inevitably affect the signal transmission, making the robot unable to work stably and execute related instructions.

[Superior Bending Resistance]: The bending resistance of robot cables should be superior. Only cables with long service life can save resources and improve work efficiency. Long-lasting cables are a top choice for businesses. Only in this way can the usage requirements be met.